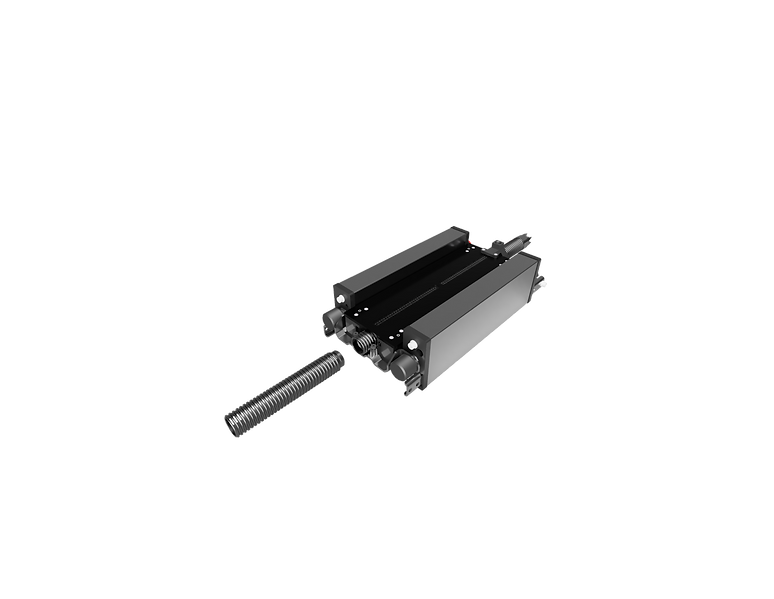

BUDDEL

Harness the Underground Power with BUDDEL's Advanced Features. Imagine a machine that transforms the way we approach trenchless construction. That's BUDDEL for you, employing the sheer force of our pneumatic muscles to achieve unparalleled strength, all within a marvelously lightweight frame. This isn't mere advancement; it's a revolutionary leap for subterranean mechanics.

Strength & Precision

While BUDDEL brings agility and strength to the table, its perfect companion, BOB enhanced his precision. Together, they offer a dual advantage: BUDDEL's revolutionary lightweight design makes it the ultimate powerhouse for tight spaces, while BOB's unique helix shapes set new industry standards for driving through loose soils and granulates.

Efficiently Engineered

But we don't stop there. Our cutting-edge software algorithms lay the groundwork for both efficient and effective tunnelling, allowing BUDDEL and BOB to work in seamless harmony. This symbiosis optimizes every element of underground construction, from the planning phase all the way to execution, minimizing disruptions and maximizing output.

Process

01

Positioning and Alignment

First BUDDEL is carefully placed in the starting pit. Great emphasis is placed on the exact alignment and secure mounting of the equipment. This initial positioning is crucial to ensure precise and efficient drilling and forms the basis for the smooth progress of the subsequent process steps.

02

Perform "Drilling"

The next step involves connecting the compressed air hose to BUDDEL. This connection is crucial for the supply of compressed air and the functionality of the device. After connecting, BUDDEL is activated.

Next, the propulsion pipes are attached piece by piece, and BUDDEL’s propulsion mechanism drives the pipes into the soil. In challenging soil conditions, a high-pressure water hose can be inserted through the pipes in advance to perform a flushing borehole, facilitating the process.

03

Retraction Process

In the final step, BUDDEL is reversed in the starting pit, and the propulsion pipes are then pulled back out. During this retraction process, a reaming tool with a flushing system can be used to widen the borehole. The empty conduit can also be attached to the reaming tool, allowing it to be pulled into place during the retraction process.

Dimension

-

Width: 320 mm

-

Height: 155 mm

-

Length: 650 mm

-

Weight: 35 kg

Operational Values

-

2 x FESTO pneumatic muscle with up to 12.000 N

-

1 x FESTO pneumatic valve

Power

-

3 x Ansmann Li-Ion 14.4 V 3500 mAh

-

Additional cable connection to power source

Sensors

-

1 x Bosch Sensortec IMU with Machine Learning